Among the most common solids that stabilize emulsions are iron sulfide, paraffin, sand, silt, clay, asphalt, scale, and corrosion products.Įmulsions are typically treated using mutual solvents. Natural surfactants, created by bacteria or during the oil generation process, can be found in many waters and crude oils, while artificial surfactants are part of many drilling, completion, or stimulation fluids. As the emulsion reaches about 25 degrees C prepare a 10 dilution of the emulsion.

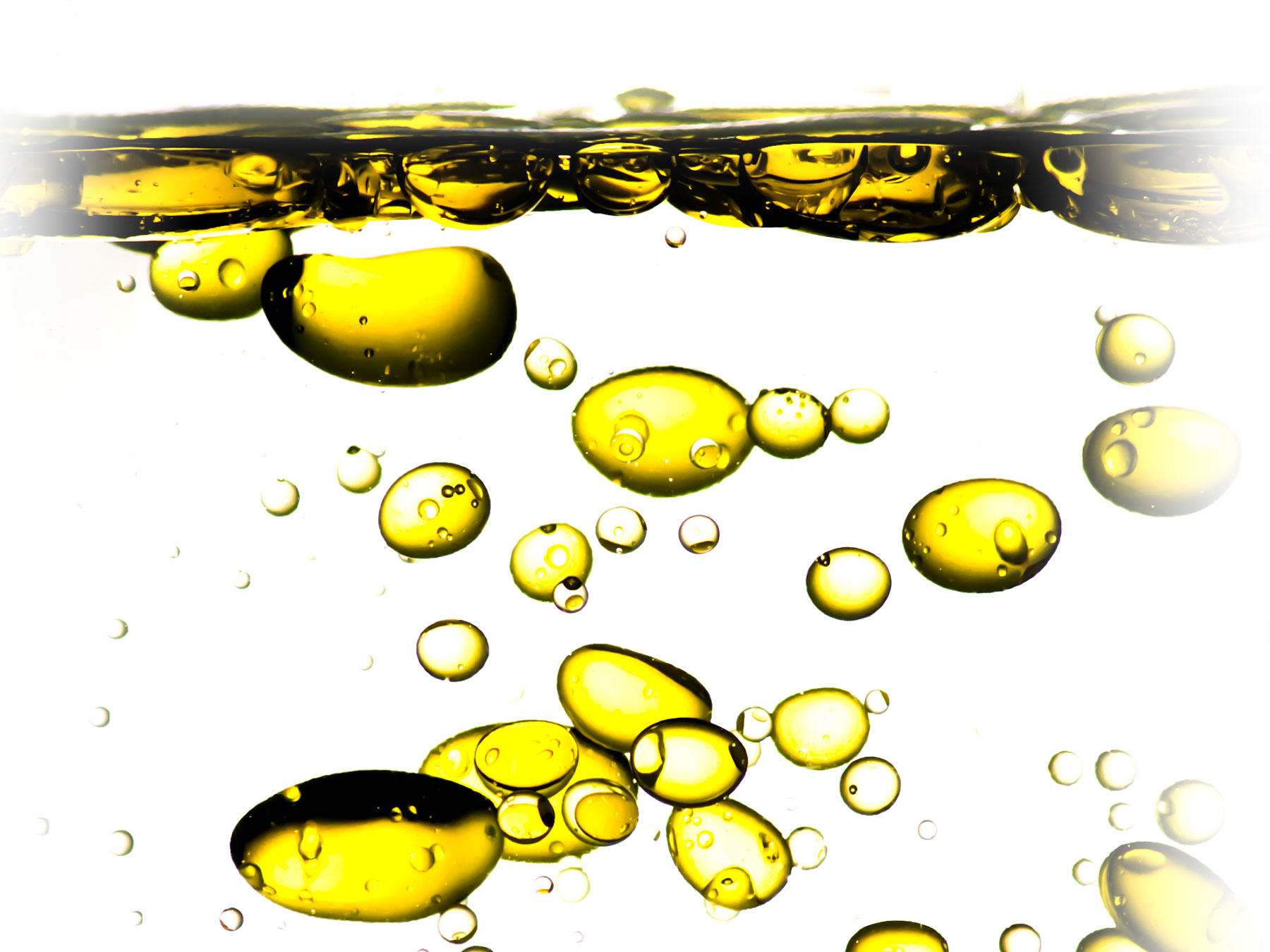

Add the tocopherol at about 40 degrees C. Start cooling while stirring the emulsion. If you use a homogenizer, apply it again for a few bursts. As the external phase is water and the oily components are dispersed as droplets, they typically consist of much more water than oils and are thus lighter, less greasy, and can easily be dispersed further with water. Blend glycerine and gum in a small beaker and add this to the emulsion. However, some natural and artificial stabilizing agents, such as surfactants and small particle solids, keep fluids emulsified. Oil-in-water emulsions are the most commonly used emulsification systems in commercial creams and lotions. Most emulsions break easily when the source of the mixing energy is removed. Emulsions are normally found in gravel packs and perforations, or inside the formation. Acidizing might change the pH from 6 or 7 to less than 4. The classification of emulsions involves three types, such as water-in-oil (W/O) emulsion, oil- in-water (O/W) emulsion and multiple emulsion 1. Emulsions can form when fluid filtrates or injected fluids and reservoir fluids (for example oil or brine) mix, or when the pH of the producing fluid changes, such as after an acidizing treatment.

A type of damage in which there is a combination of two or more immiscible fluids, including gas, that will not separate into individual components. A standard w/o emulsion composition of 4.5 (v/v) Span 80, 0.5 (v/v) Tween 80 in 0.95 mL of mineral oil (23), and 50 L of an ATPS consisting of 10 (w/w) dextran 10 kDa and 7 (w/w) PEG 8 kDa was chosen to evaluate the potential of w/o droplets in encapsulating multiple aqueous phases.

0 kommentar(er)

0 kommentar(er)